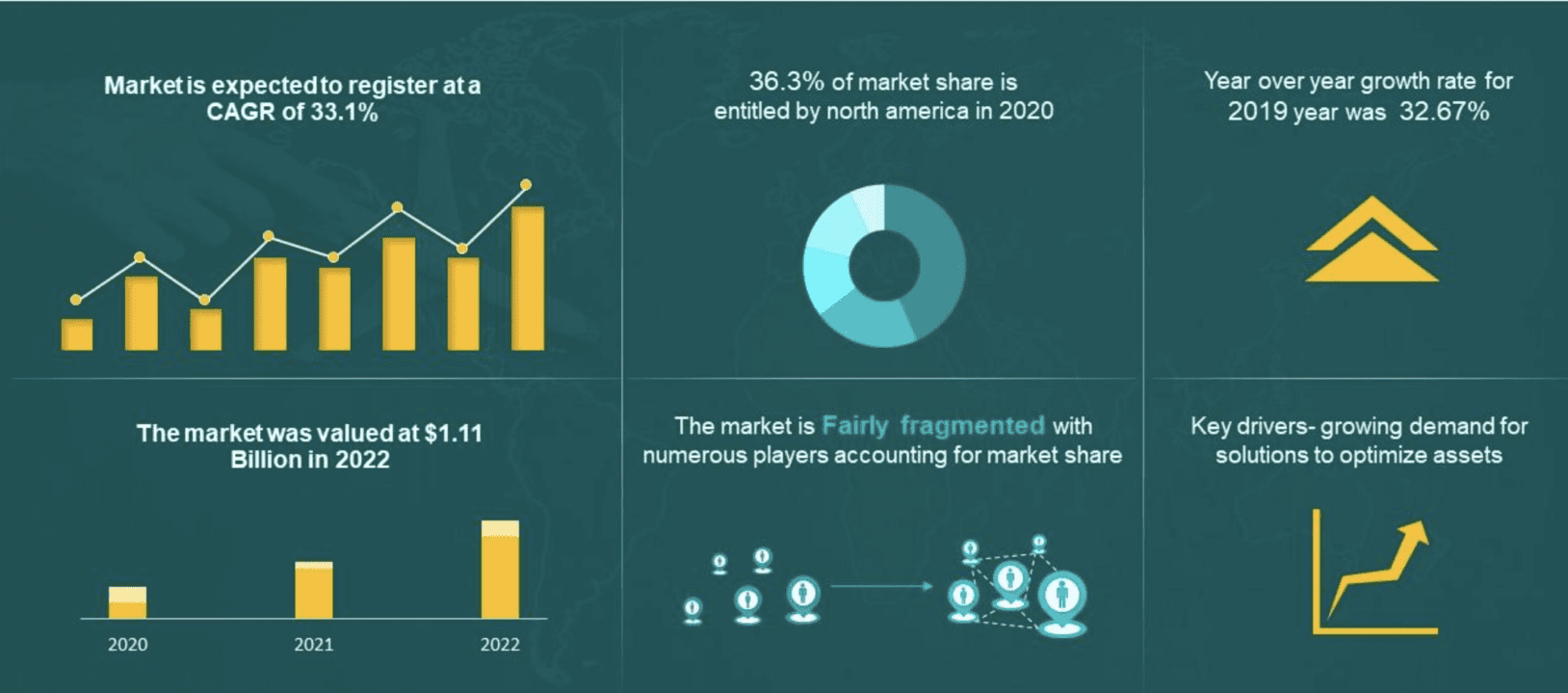

Data analytics is transforming production in the fast changing manufacturing sector of today. Using enormous volumes of data will help manufacturers maximise processes, lower expenses, and improve product quality. Our speciality at Cobit Solutions is offering manufacturers staying ahead of the curve modern data-driven solutions.

We’ll discuss what manufacturing data and analytics is, how it works, its advantages, and how you may apply it in your manufacturing operations in this blog.

In this blog post, we will explore the concept of Manufacturing Data Analytics and its significance in the modern manufacturing industry.

Table of Contents

What Is Manufacturing Data Analytics?

Manufacturing data analytics refers to the systematic approach of collecting, processing, and analyzing data from various manufacturing processes to gain actionable insights. By leveraging data analytics, manufacturers can optimize operations, enhance production efficiency, and improve overall product quality. This involves utilizing cutting-edge technologies to interpret data from machinery, sensors, and supply chain systems, allowing manufacturers to make informed decisions that drive business success.

How Does Manufacturing Data Analytics Operate?

Data analytics and manufacturing operates through a series of well-defined stages that transform raw data into valuable insights. The process begins with data collection from various sources within the production environment, such as IoT devices, ERP systems, and SCADA systems. This data is then integrated into a centralized database to ensure seamless connectivity and consistency.

Once collected, the data undergoes processing through advanced analytical tools and techniques. Data transformation is a crucial step, ensuring that the data is clean, normalized, and ready for analysis. Modern analytical approaches, including machine learning and AI, are applied to examine patterns, predict trends, and uncover hidden insights.

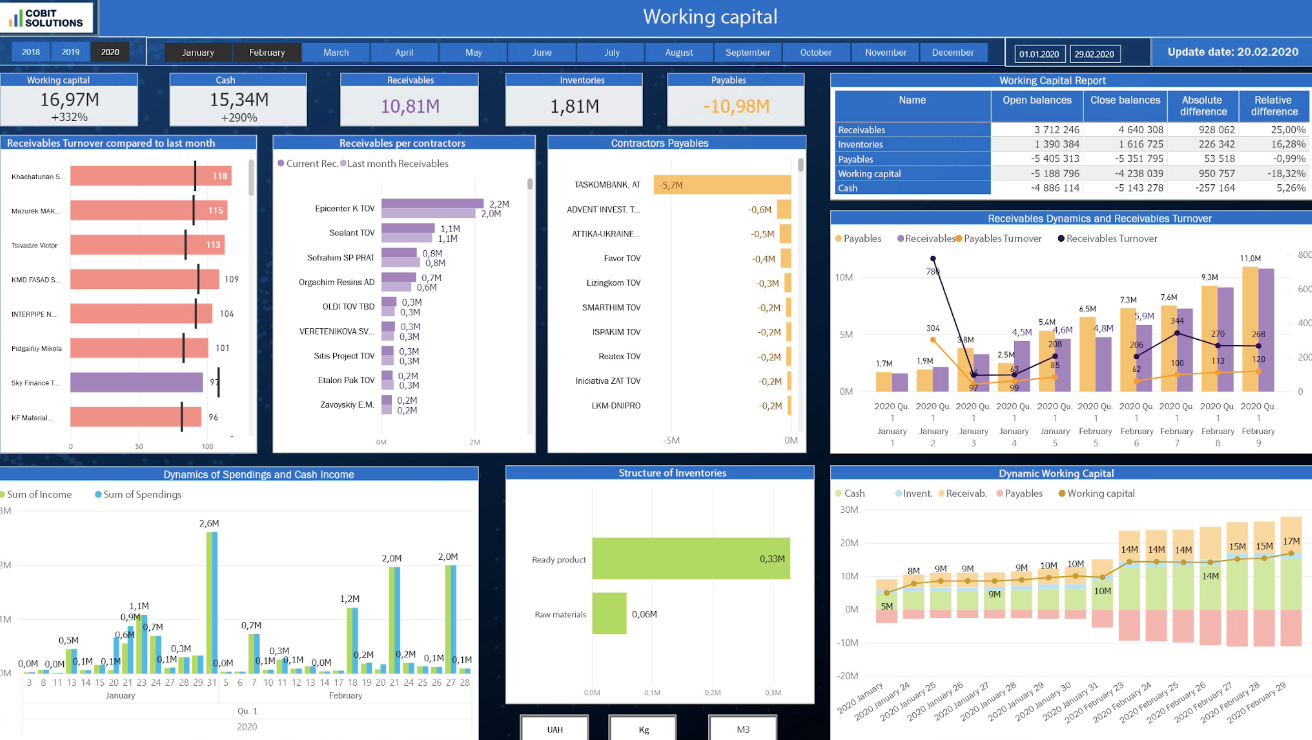

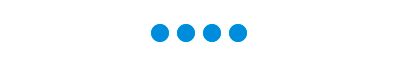

Visualization plays a vital role in manufacturing and data analytics, converting complex data sets into interactive dashboards and reports. These visualizations provide manufacturers with a clear view of key performance indicators (KPIs) and metrics, enabling them to monitor operations in real-time and make data-driven decisions swiftly.

What Can You Gain from Manufacturing Data Analytics?

The benefits of data analytics manufacturing are manifold, offering manufacturers a competitive edge in a rapidly evolving industry. Here are some key gains:

- Increased Efficiency: By identifying inefficiencies and bottlenecks, manufacturers can streamline processes, optimize workflows, and boost productivity.

- Cost Reduction: Predictive maintenance reduces downtime and maintenance costs by anticipating equipment failures. Energy management analytics help optimize energy usage, leading to significant cost savings.

- Improved Quality: Continuous monitoring and real-time data analysis ensure that products meet high-quality standards, reducing defects and enhancing customer satisfaction.

- Enhanced Decision-Making: Data-driven insights provide manufacturers with the information needed to make strategic decisions, such as resource allocation and production planning.

- Supply Chain Optimization: Analyzing supply chain data improves inventory management, reduces lead times, and enhances supplier performance.

- Innovation and Competitiveness: By leveraging data analytics, manufacturers can innovate and stay ahead of the competition, responding quickly to market trends and customer demands.

What Challenges Can Manufacturing Data Analysis Assist You With?

Manufacturing data analysis can assist manufacturers in overcoming several challenges that impact their operations and profitability:

- Operational Inefficiencies: Identifying and addressing inefficiencies in production processes to enhance productivity.

- Quality Control Issues: Monitoring production in real-time to ensure consistent product quality and reduce defects.

- Supply Chain Disruptions: Optimizing inventory levels and supplier performance to minimize disruptions and improve supply chain resilience.

- Equipment Downtime: Predicting equipment failures and scheduling maintenance to avoid unexpected downtime and extend machinery lifespan.

- Energy Waste: Analyzing energy consumption patterns to optimize usage and reduce environmental impact.

- Market Volatility: Using predictive analytics to forecast demand and adjust production schedules accordingly.

- Regulatory Compliance: Ensuring manufacturing processes comply with industry regulations and standards to avoid penalties and maintain reputation.

How to Roll Out Data Analytics in Manufacturing?

Rolling out data analytics in manufacturing requires a strategic approach that aligns with the organization’s goals and capabilities. Here are the key steps to implement manufacturing data analytics successfully:

Define Objectives:

Clearly outline the goals and objectives you want to achieve with data analytics. This could include improving efficiency, reducing costs, or enhancing product quality.

Data Collection:

Gather data from various sources within the production environment, such as machinery sensors, ERP systems, and supply chain management tools.

Choose the Right Tools:

Select the appropriate analytical tools and technologies that fit your needs and budget. Consider factors such as scalability, integration capabilities, and ease of use.

Data Processing and Analysis:

Use advanced analytical techniques to process and analyze the data. This involves data cleansing, integration, and transformation to ensure accuracy and consistency.

Visualization and Reporting:

Develop interactive dashboards and reports that provide real-time insights into key metrics and KPIs. These visualizations should be tailored to meet the needs of different stakeholders.

Implementation and Monitoring:

Apply the insights gained from data analysis to optimize processes and improve performance. Continuously monitor the results and make adjustments as needed.

Training and Change Management:

Train employees on how to use data analytics tools and interpret insights. Foster a culture of data-driven decision-making across the organization.

The Next Phase of Manufacturing Analytics

The future of manufacturing analytics is promising, with advancements in AI, machine learning, and IoT driving innovation. As these technologies continue to evolve, manufacturers will have access to even more sophisticated tools and techniques for analyzing data.

The next phase of manufacturing analytics will focus on greater integration and automation. By connecting data analytics with other technologies, such as robotics and automation, manufacturers can achieve higher levels of efficiency and productivity. This integration will enable seamless data flow across the entire manufacturing ecosystem, from production lines to supply chains.

Additionally, the rise of edge computing and real-time analytics will allow manufacturers to process data closer to the source, reducing latency and enabling faster decision-making. This will be particularly beneficial for applications that require immediate responses, such as predictive maintenance and quality control.

Sustainability will also play a significant role in the next phase of manufacturing analytics. By optimizing energy usage and reducing waste, manufacturers can minimize their environmental impact and support global sustainability goals.

Successful Integration Projects

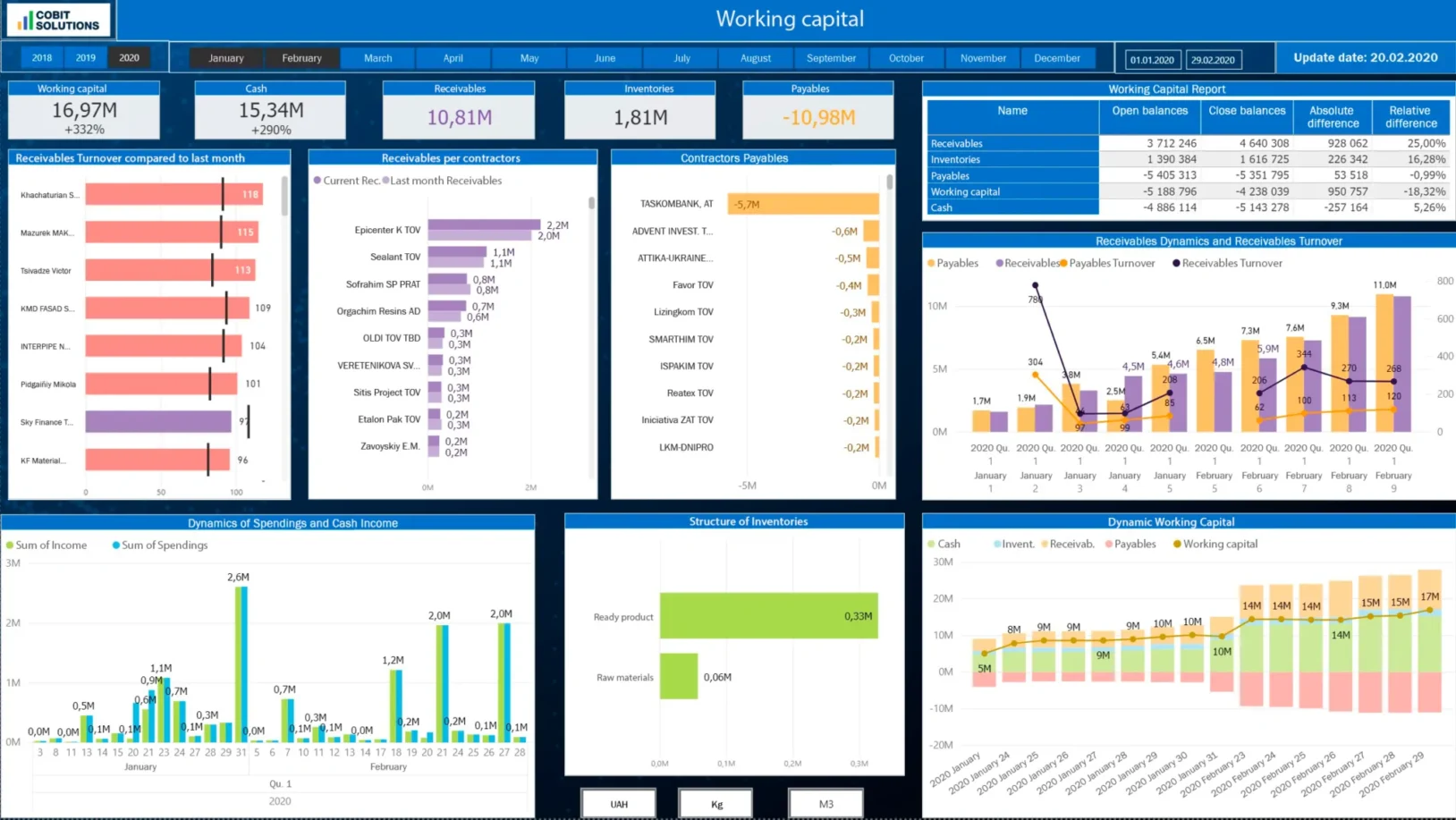

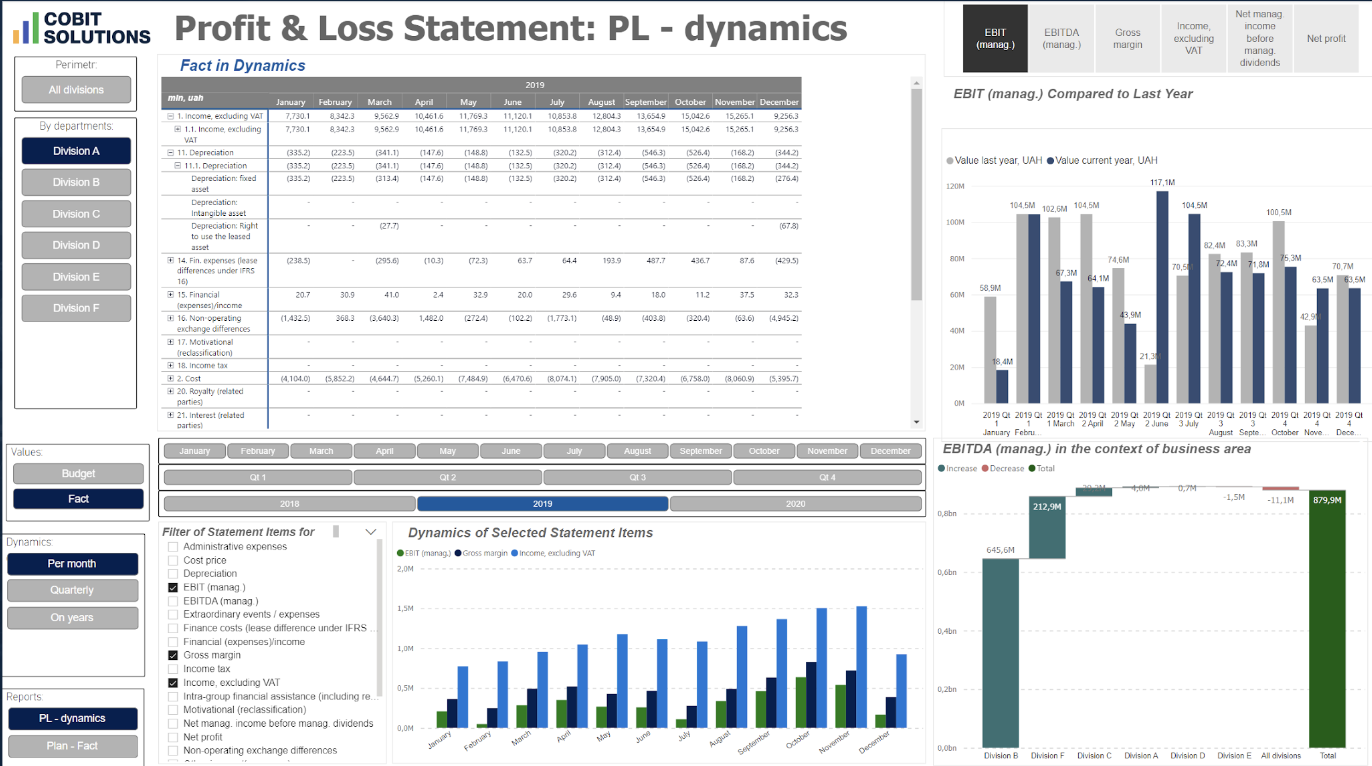

Cobit Solutions has a history of successful Power BI integrations, enhancing business operations across various industries.

Working with Cobit Solutions will let your company use innovative Power BI tools to convert data into strategic insights. Our services are meant to maximize company operations, improve financial control, and offer thorough access to several performance criteria.

Our tailored Dashboards for Manufacturing offer the depth and adaptability needed to support wise decision-making all around your business. Our solutions are made to fit your requirements regardless of your objectives—that of better financial forecasts, simpler reporting systems, or improved customer analytics.

Ready to transform your manufacturing processes with Power BI? We offer expert consulting services to help you implement robust data analytics solutions tailored to your specific needs. Contact us today to learn how we can help.

Cobit Solutions: Your Partner in Manufacturing Data Analytics

At Cobit Solutions, we specialize in implementing robust data analytics solutions tailored to the specific needs of manufacturers. Established in 2018, Cobit Solutions combines expertise in Power BI, Azure, and other advanced technologies to provide comprehensive business intelligence and data-driven solutions. Our services are designed to help manufacturers optimize operations, reduce costs, and improve product quality.

With a focus on speed, affordability, and expertise, Cobit Solutions offers guarantees on our services, ensuring that you receive the highest level of support and results. Whether you are looking to enhance your manufacturing processes, improve supply chain efficiency, or achieve sustainability goals, our team of experts is here to assist you every step of the way.

Ready to harness the power of data analytics in your manufacturing processes? Contact Cobit Solutions today to learn how we can help you stay competitive in today’s dynamic market.

Developing the business becomes more comfortable when you regulate the workflows according to the fast reports with interactive analytics.

Dashboards creation

Whether you are implementing a new BI tool or building an entire system from scratch, Cobit Solutions team can help you meet your business intelligence needs. Our seasoned professionals will provide you with an effective BI system to make your business succeed. Power BI developing services can be used on a monthly or hourly basis, with subscription of fixed-price. You can leave the offer query for our specialist to connect with you. Let’s discuss your objective. It will cost you 40 minutes of online-meeting.

You might also be interested in the article by the owner of Cobit Solutions Why does my company need business intelligence?

Read more on real cases of BI system implementation in different industries on our Blog

![brain [:en]brain[:]](https://cobit-solutions.com/en/wp-content/uploads/sites/2/elementor/thumbs/brain-qs6fjfc8oa0rt8hsk54chu973hhgyvaqelmtb9zw5c.png)

![art [:en]art[:]](https://cobit-solutions.com/en/wp-content/uploads/sites/2/elementor/thumbs/art-qs6fkkp5gryi6k5v1g3yaxsw0a50al0ky4sfucv65k.png)

![clock [:en]clock[:]](https://cobit-solutions.com/en/wp-content/uploads/sites/2/elementor/thumbs/clock-qs6fnjuqo3o2rmi2gxbefss0yd5gr1obn0pj4zvou8.png)

![pen [:en]pen[:]](https://cobit-solutions.com/en/wp-content/uploads/sites/2/elementor/thumbs/pen-qs6fqqj1tw1241vhvavvvzu9fdg8u4bkqsaror5nr4.png)

![Untitled_design__28_-removebg-preview (1) [:en]Untitled_design__28_-removebg-preview (1)[:]](https://cobit-solutions.com/en/wp-content/uploads/sites/2/elementor/thumbs/untitled_design__28_-removebg-preview-1-e1722362724916-qrvt4vt0ir0yp8i3osc3lo1nj3c5y98h2dxrjkcxk8.png)

![Untitled_design__28_-removebg-preview (1) [:en]Untitled_design__28_-removebg-preview (1)[:]](https://cobit-solutions.com/en/wp-content/uploads/sites/2/elementor/thumbs/untitled_design__28_-removebg-preview-1-e1722362724916-qrvt4vt02ynuir5yhz82ua28r90s182tcjhi4nsby8.png)