Manufacturing organisations are always looking for creative solutions to improve output, save expenses, and guarantee quality in the competitive industrial scene of today. Data analytics is among the most powerful tools available for reaching these goals. Using data analytics would help manufacturers to have thorough understanding of their operations, thereby guiding their decisions and promoting corporate development.

With an eye on business intelligence for manufacturing, Microsoft Power BI consulting services, and Power BI manufacturing dashboards, this blog will investigate the advantages and relevance of data analytics in the manufacturing sector.

In this blog post, we will explore the concept of Manufacturing Data Analytics and its benefits in the modern manufacturing industry.

Benefits and Importance of Data Analytics in Manufacturing

In today’s competitive manufacturing landscape, data analytics plays a crucial role in driving efficiency, reducing costs, and enhancing product quality. The benefits of data analytics in manufacturing industry extend beyond mere operational improvements; they enable manufacturers to make smarter decisions, optimize production processes, and stay ahead of the competition. In this blog, we will explore the importance of data analytics in manufacturing industry and how it can transform operations for the better.

Table of Contents

Manufacturers can find inefficiencies and bottlenecks by means of data analysis spanning several sources, including supply chains, equipment, and manufacturing lines. This makes it possible to apply focused improvements, hence raising operational effectiveness.

Predictive maintenance—where possible equipment faults are found before they start—is made possible in manufacturing by data analytics. This proactive strategy lowers repair costs, increases machinery lifetime, and lessens downtime.

By means of supply chain operations, data analytics manufacturing solutions assist businesses maximise inventory levels, lower lead times, and increase general supply chain effectiveness.

Defining Data Analytics in Manufacturing

Data analytics in manufacturing involves the systematic collection, processing, and analysis of data generated from various sources within the manufacturing environment. This includes data from machinery, sensors, supply chain systems, and more. By leveraging advanced technologies and analytical tools, manufacturers can gain valuable insights into their operations, identify patterns, and make informed decisions that drive business success.

Different Types of Data Analytics

Data analytics in manufacturing can be categorized into several types, each serving a unique purpose:

Descriptive Analytics:

This type of analytics focuses on summarizing historical data to understand past performance. It helps manufacturers identify trends and patterns in their operations.

Predictive Analytics:

Predictive analytics uses data science in manufacturing to forecast future trends and potential issues. By analyzing historical data, manufacturers can anticipate equipment failures, demand fluctuations, and other critical factors.

Prescriptive Analytics:

This advanced form of analytics provides actionable recommendations based on data analysis. It helps manufacturers optimize processes, allocate resources, and make strategic decisions.

Diagnostic Analytics:

This type of analytics is used to identify the root causes of specific problems or anomalies in manufacturing operations. It helps manufacturers understand why certain issues occur and how to address them.

Main Benefits of Data Analytics in Manufacturing

There are always pros and cons. However, the importance of data analytics in the manufacturing industry cannot be overstated. Here are some of the main benefits:

Cutting Costs 💰

One of the most significant benefits of data analytics in manufacturing is cost reduction. By analyzing data from various sources, manufacturers can identify inefficiencies and optimize resource utilization. Predictive maintenance, for example, allows manufacturers to anticipate equipment failures and schedule maintenance proactively, reducing downtime and repair costs. Additionally, energy management analytics help manufacturers optimize energy usage, leading to substantial cost savings.

Smarter Choices 🧠

Data analytics for manufacturing enables smarter decision-making by providing manufacturers with actionable insights. By analyzing data from production processes, supply chains, and market trends, manufacturers can make informed decisions that align with their strategic goals. This includes optimizing production schedules, managing inventory levels, and selecting reliable suppliers. Data-driven decision-making ensures that manufacturers can respond quickly to changing market conditions and customer demands.

Better Productivity 🚀

Data analytics in manufacturing enhances productivity by streamlining operations and optimizing workflows. By identifying bottlenecks and inefficiencies in production processes, manufacturers can implement strategies to improve efficiency and increase output. Real-time monitoring and data analysis also allow manufacturers to adjust operations on the fly, ensuring that production runs smoothly and efficiently.

Happy Customers 😊

The importance of data analytics in manufacturing extends to customer satisfaction. By ensuring consistent product quality and timely delivery, manufacturers can meet customer expectations and build strong relationships. Data analytics helps manufacturers monitor quality metrics in real-time, enabling them to address issues promptly and maintain high standards. Additionally, by analyzing customer feedback and market trends, manufacturers can develop products that better meet customer needs.

Use Cases For Manufacturing Analytics

The applications of data analytics in manufacturing are vast and varied. Here are some key use cases:

Predictive Maintenance 🔧

Predictive maintenance is a prime example of how data analytics can benefit manufacturing operations. By collecting data from machinery and sensors, manufacturers can predict when equipment is likely to fail and schedule maintenance accordingly. This proactive approach minimizes downtime, extends equipment lifespan, and reduces maintenance costs.

Forecasting Demand 📈

Data analytics in the manufacturing industry is essential for accurate demand forecasting. By analyzing historical sales data, market trends, and external factors, manufacturers can predict future demand and plan production schedules accordingly. This ensures that manufacturers can meet customer demand without overproducing or underproducing, optimizing inventory levels and reducing waste.

Streamlining The Supply Chain 🚚

Data analytics plays a crucial role in streamlining supply chain operations. By analyzing data from suppliers, logistics providers, and inventory systems, manufacturers can optimize supply chain processes, reduce lead times, and improve supplier performance. This leads to more efficient operations and ensures that materials and products are available when needed.

Quality Assurance 🔍

Quality assurance is a critical aspect of manufacturing, and data analytics can significantly enhance quality control processes. By monitoring production data in real-time, manufacturers can identify deviations from quality standards and address issues immediately. This ensures consistent product quality, reduces defects, and enhances customer satisfaction.

Optimizing Prices 💵

Data analytics for manufacturing can also be used to optimize pricing strategies. By analyzing market data, competitor pricing, and customer preferences, manufacturers can develop pricing models that maximize profitability while remaining competitive. This data-driven approach ensures that manufacturers can respond to market changes and adjust prices as needed.

Developing New Products 🛠️

The development of new products is another area where data analytics can provide significant benefits. By analyzing customer feedback, market trends, and emerging technologies, manufacturers can identify opportunities for innovation and develop products that meet evolving customer needs. Data analytics helps manufacturers make informed decisions throughout the product development process, from concept to launch.

All things considered, data analytics in manufacturing is a game-changer with several advantages ranging from better operational efficiency to cost-cutting and product quality enhancement. Tools like Microsoft Power BI enable manufacturers to have the knowledge required to remain competitive in the fast-paced industrial scene of today by means of business intelligence for manufacturing. Effective data collection in manufacturing is crucial to this process, as it provides the raw data needed for insightful analysis. Manufacturing firms can maximize their data by using Microsoft Power BI consulting services, therefore promoting ongoing development.

Data analytics will only become more important as the manufacturing sector changes. Businesses who welcome data-driven decision-making will be more suited to survive in a market getting more competitive. Thus, if you haven’t already, it’s time to investigate the potential of data analytics for manufacturing and advance your operations.

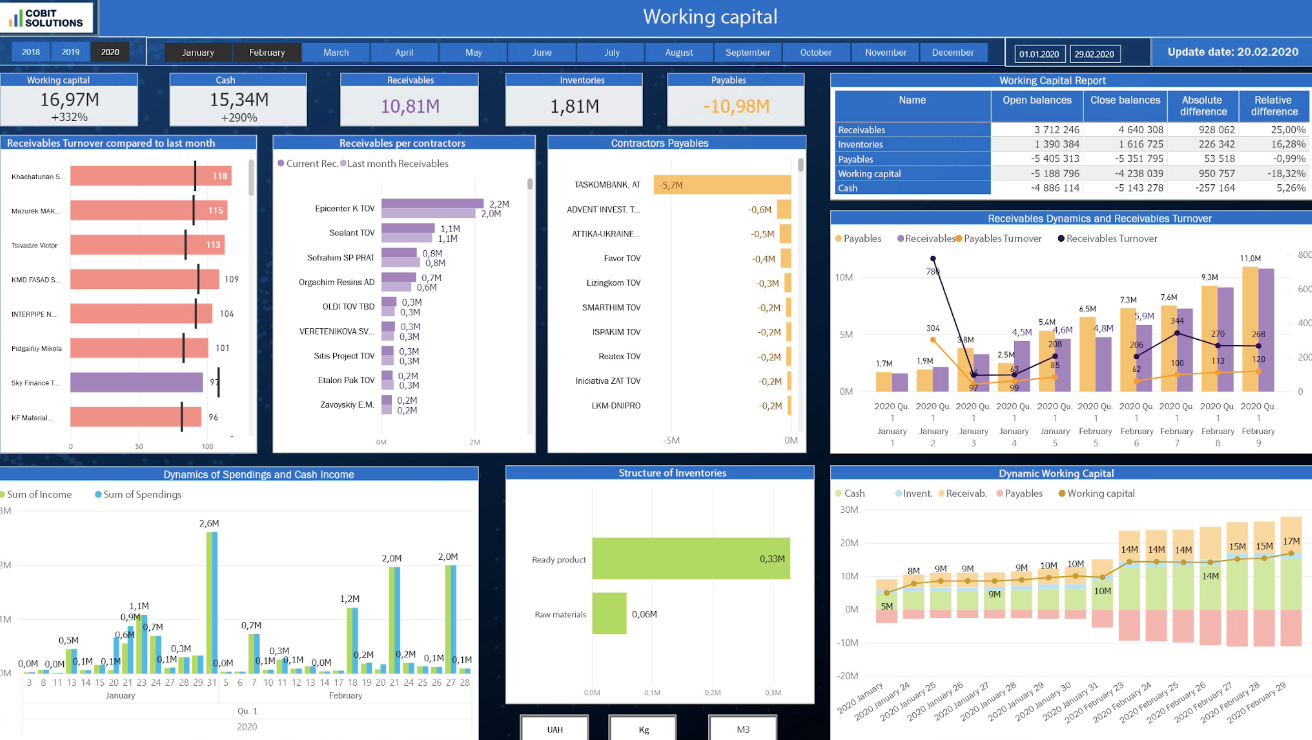

Successful Integration Projects

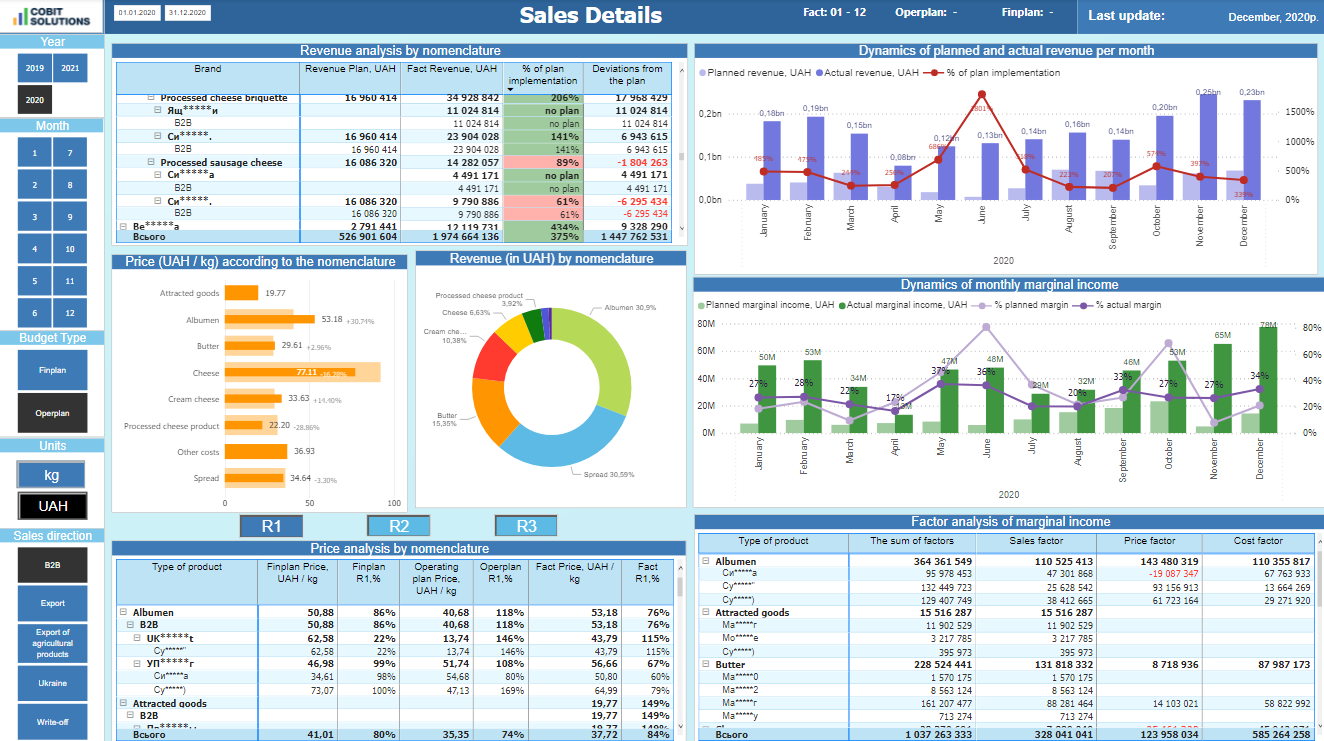

Cobit Solutions has a history of successful Power BI integrations, enhancing business operations across various industries.

Working with Cobit Solutions will let your company use innovative Power BI tools to convert data into strategic insights. Our services are meant to maximize company operations, improve financial control, and offer thorough access to several performance criteria.

Our tailored Dashboards for Manufacturing offer the depth and adaptability needed to support wise decision-making all around your business. Our solutions are made to fit your requirements regardless of your objectives—that of better financial forecasts, simpler reporting systems, or improved customer analytics.

The developed perfectly looking Bl templates allow our clients to quickly build their first report in Power Bl and include the most relevant KPIs for reports. – Anna Odrynska, CSO at Alpha Serve

Get in Touch with Us

Ready to use data analytics to revolutionise your manufacturing processes? For professional Microsoft Power BI consulting services, get in touch Cobit Solutions right now. Let us assist you to create unique Power BI manufacturing dashboards and discover the whole possibilities of your data.

The benefits and importance of data analytics in manufacturing are clear. By leveraging data analytics, manufacturers can optimize operations, reduce costs, and improve product quality. From predictive maintenance to demand forecasting, data analytics offers a wide range of applications that drive efficiency and competitiveness. As the manufacturing industry continues to evolve, the role of data analytics will only become more critical.

At Cobit Solutions, we specialize in helping manufacturers implement robust data analytics solutions tailored to their specific needs. Ready to harness the power of data analytics in your manufacturing processes? Contact us today to learn how we can help you achieve your business goals.

Developing the business becomes more comfortable when you regulate the workflows according to the fast reports with interactive analytics.

Dashboards creation

You might also be interested in the article by the owner of Cobit Solutions Why does my company need business intelligence?

Read more on real cases of BI system implementation in different industries on our Blog

![Untitled_design__28_-removebg-preview (1) [:en]Untitled_design__28_-removebg-preview (1)[:]](https://cobit-solutions.com/en/wp-content/uploads/sites/2/elementor/thumbs/untitled_design__28_-removebg-preview-1-e1722362724916-qrvt4vt0ir0yp8i3osc3lo1nj3c5y98h2dxrjkcxk8.png)

![Untitled_design__28_-removebg-preview (1) [:en]Untitled_design__28_-removebg-preview (1)[:]](https://cobit-solutions.com/en/wp-content/uploads/sites/2/elementor/thumbs/untitled_design__28_-removebg-preview-1-e1722362724916-qrvt4vt02ynuir5yhz82ua28r90s182tcjhi4nsby8.png)