Staying ahead of the competition requires more than just efficiency and quality. Leveraging business intelligence for manufacturing enables quick and accurate data-driven decision-making, which is paramount for success.

This is where manufacturing Power BI dashboard comes into play, providing real-time insights, streamlining processes, and facilitating smarter business choices.

In this article, we will delve into the power of manufacturing dashboards, showcasing their immense value and how Cobit Solutions can be your key to success.

Power BI in Manufacturing Industry:

Unveiling the Hidden Potential

Manufacturing companies generate an enormous amount of data throughout their operations. However, without proper analysis and interpretation through business intelligence for manufacturing and manufacturing business analytics, this data remains untapped potential.

Enter data analytics for manufacturing — a game-changer that empowers businesses to harness actionable insights from complex datasets.

By employing advanced analytics techniques or a Power BI production dashboard, manufacturers can leverage business intelligence in manufacturing to unlock patterns, identify bottlenecks, optimize workflows, and improve overall performance.

Revolutionizing Decision - Making with Power BI for the

Manufacturing Industry

In the dynamic manufacturing environment, timely and informed decision-making is crucial. Power BI for manufacturing, combined with manufacturing business intelligence, provides comprehensive visibility into operations, supply chains, sales, and other critical aspects.

With interactive dashboards, key performance indicators, and data visualizations, manufacturing business intelligence solutions provide decision-makers with a holistic understanding of their business landscape, facilitating strategic planning, risk mitigation, and improved efficiency.

Manufacturing data analytics is a vital element for the company management and meeting the strategic planning. The Power business intelligence tools have shown their significance for the decision makers because they are available from any point in the world, and are regularly updated for the moment you see the analytical report.

Managers and directors can carry on with their workflows until they need dashboard data for informed decisions. Meanwhile, business intelligence in the manufacturing industry operates through cloud-based services, continuously updating and gathering data from ERP, API, CRM, databases, Excel, and other IT systems to create analytical reports.

Big data analytics in manufacturing includes five main dashboards you will need to check the results and correct the workflow.

Five Manufacturing Dashboards for Big Data Analytics:

#1 - Power BI Production

CEO Dashboard

The CEO dashboard is the most handy manufacturing BI report for decision-makers, reflecting key metrics of the company’s activity, including revenue, operational profit, and other structures.

Sales dynamics, margin levels, account balances, costs, profitability, net profit, and the current state of accounts receivable and payable are all reflected in this Power BI dashboard. Leveraging business intelligence manufacturing, these data points are analyzed dynamically and by key business activity areas, enabling the CEO to assess major business trends and daily operations effectively.

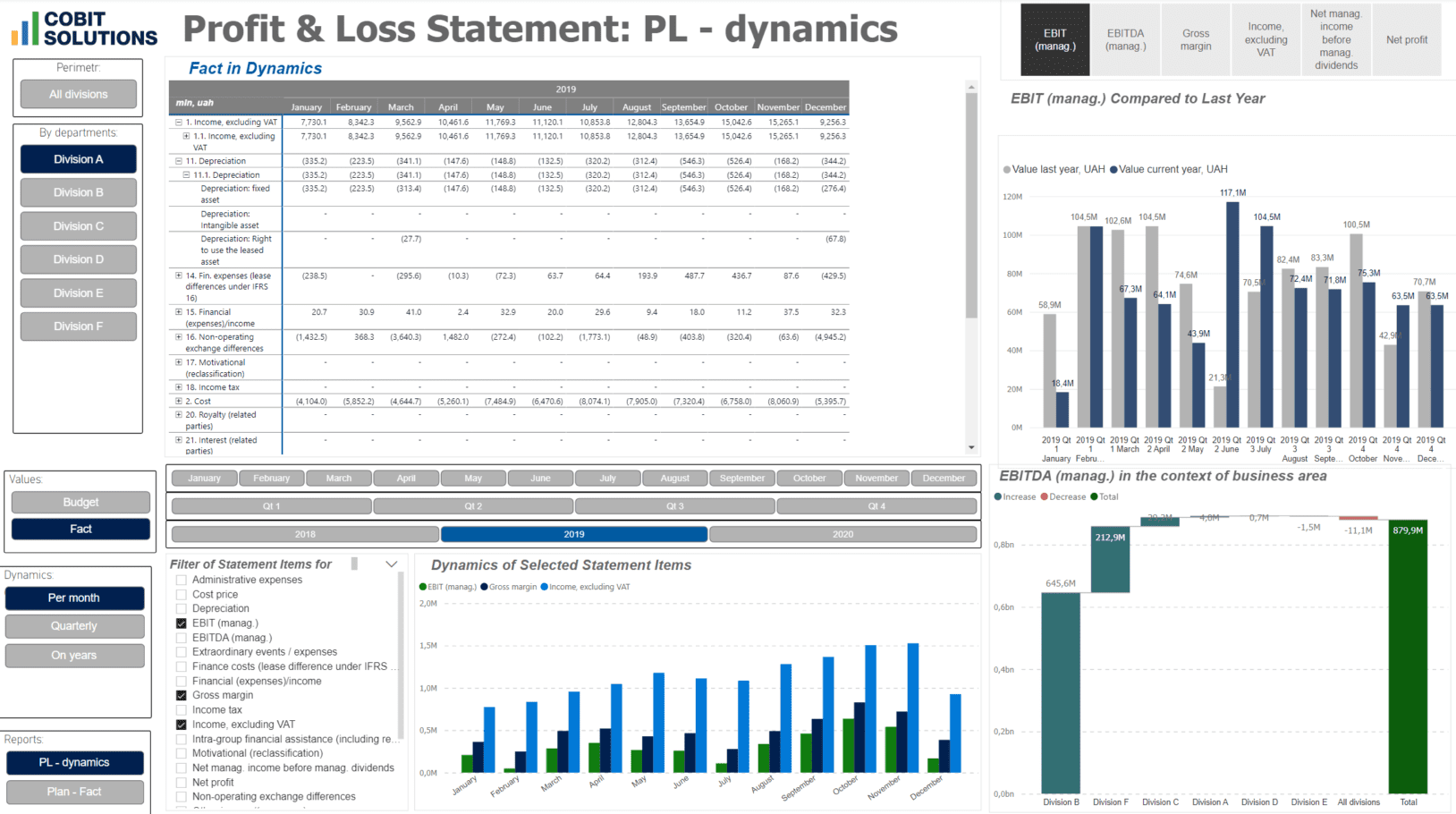

#2 - Power BI Manufacturing P&L Dashboard

P&L dashboard is increasing financial control of manufacturing companies. To tell the truth this Power BI production dashboard is important for all types of businesses. It is connected with the calculation of sales, gross profit, financial incomes and expenses to get the net profit.

The main metrics here are revenues from sales, cost of goods sold, gross profit and expenses of the company connected with operational (administrative salaries, rents, etc.) and non-operational activity, financial and other incomes and costs to calculate net profit. Net profit is the result of P&L.

Cost of Goods Sold (CoGS) is not always shown by products, because there are general manufacturing expenses too. Moreover, manufacturing companies can use different principles to define Cost.

#3 - Power BI Manufacturing

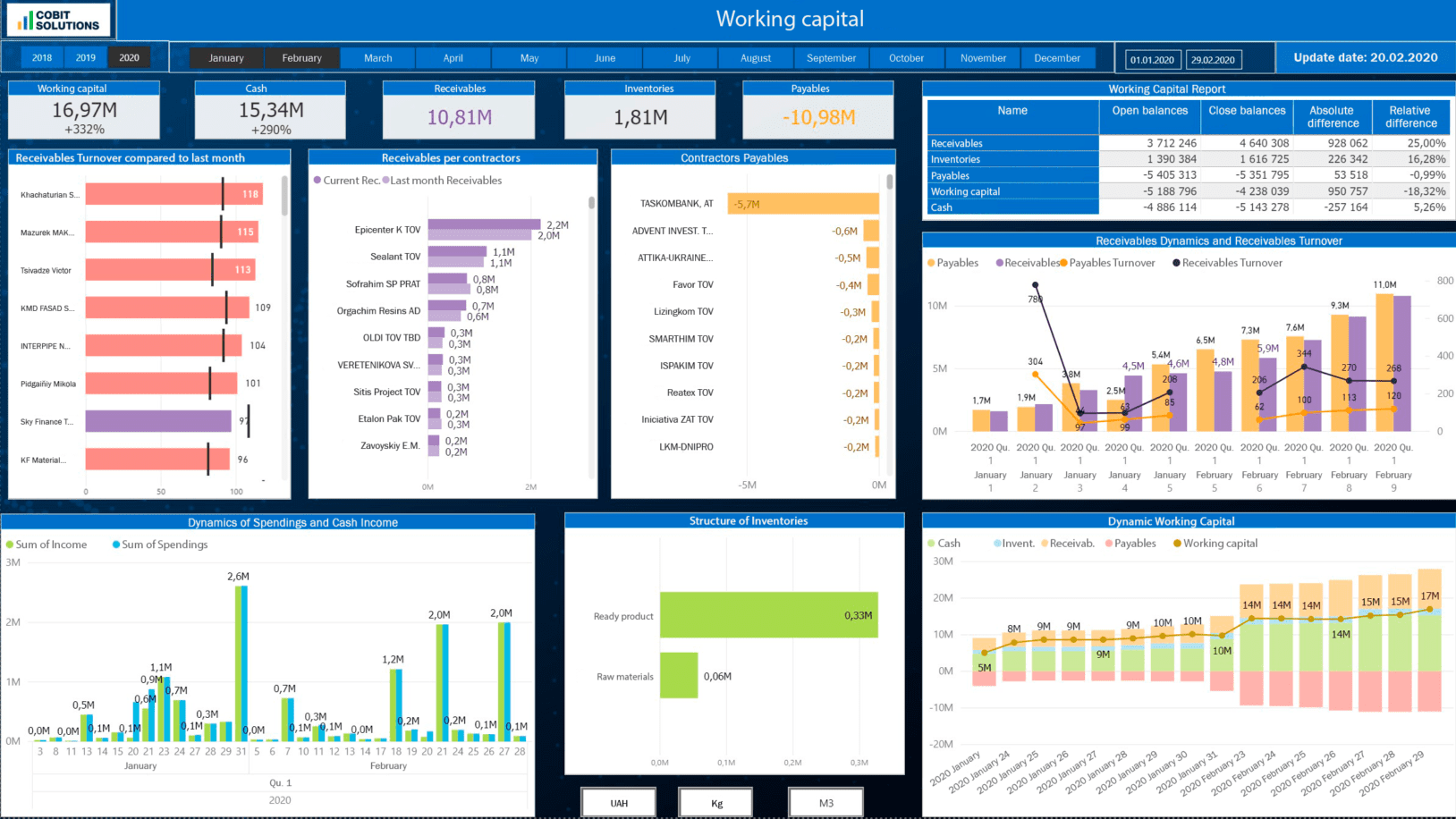

Working Capital Dashboard

The working capital dashboard is a vital financial indicator that highlights the shareholders’ capital tied up in a company’s current assets. It is applicable to all types of companies and focuses on accounts receivable, payable, stock, and cash balances. Leveraging business analytics in the manufacturing industry, working capital is calculated by summing current assets such as cash balances, accounts receivable, and inventory, then subtracting short-term loan debt, providing key insights in the production dashboard Power BI report.

Finally, it reflects the sum of frozen shareholders’ capitals. When working capital is positive (10 million), it means that this sum is frozen in the current assets.

#4 - Production Marginal Income

Factor Analysis Dashboard

Marginal income factor analysis dashboard is connected with the Revenue and Cost of goods Sold.

Factor analysis means the affection of the sales changes (by amount, by price) and reflects which factors affected the marginal income.

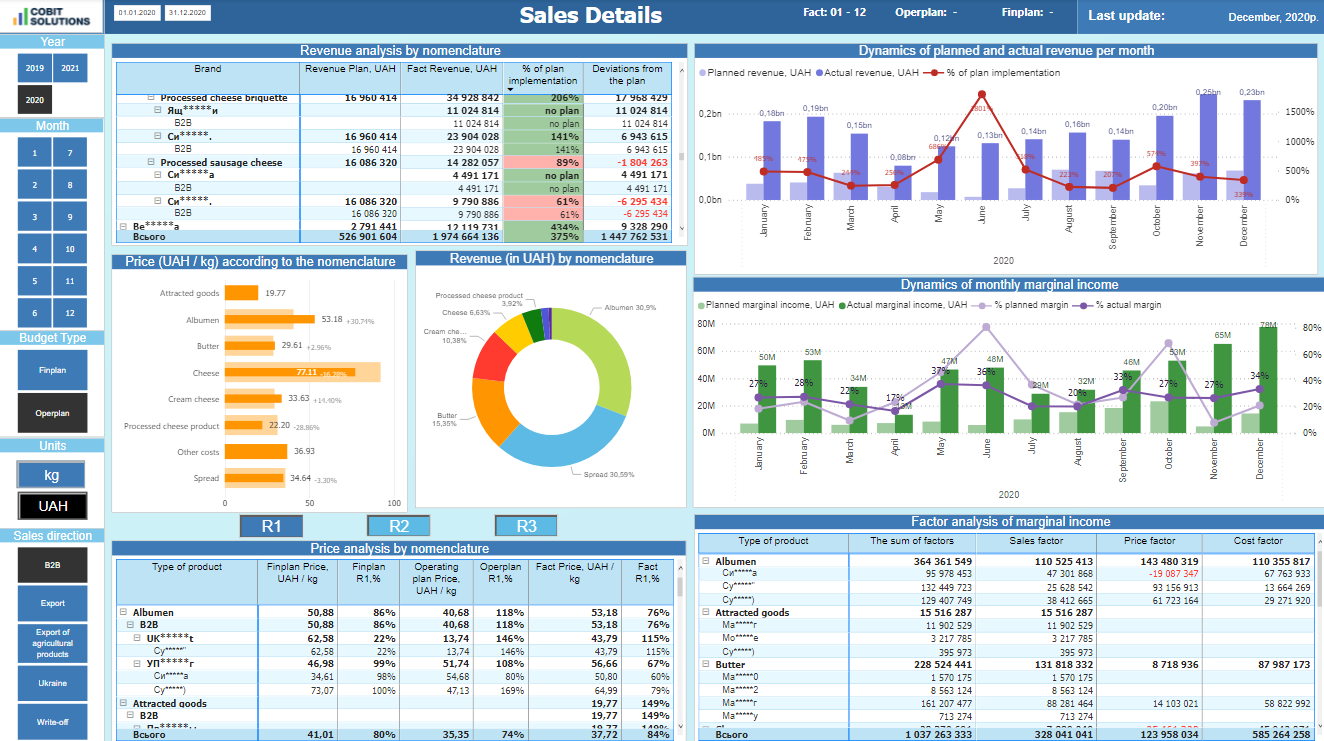

#4 manufacturing dashboard Power BI reflects the revenue plan, factorial plan, % of plan implementation, deviations from the plan; dynamics of planned and actual revenue per month; dynamics of monthly marginal income, etc.

#5 - Manufacturing Production

Cost Details Dashboard

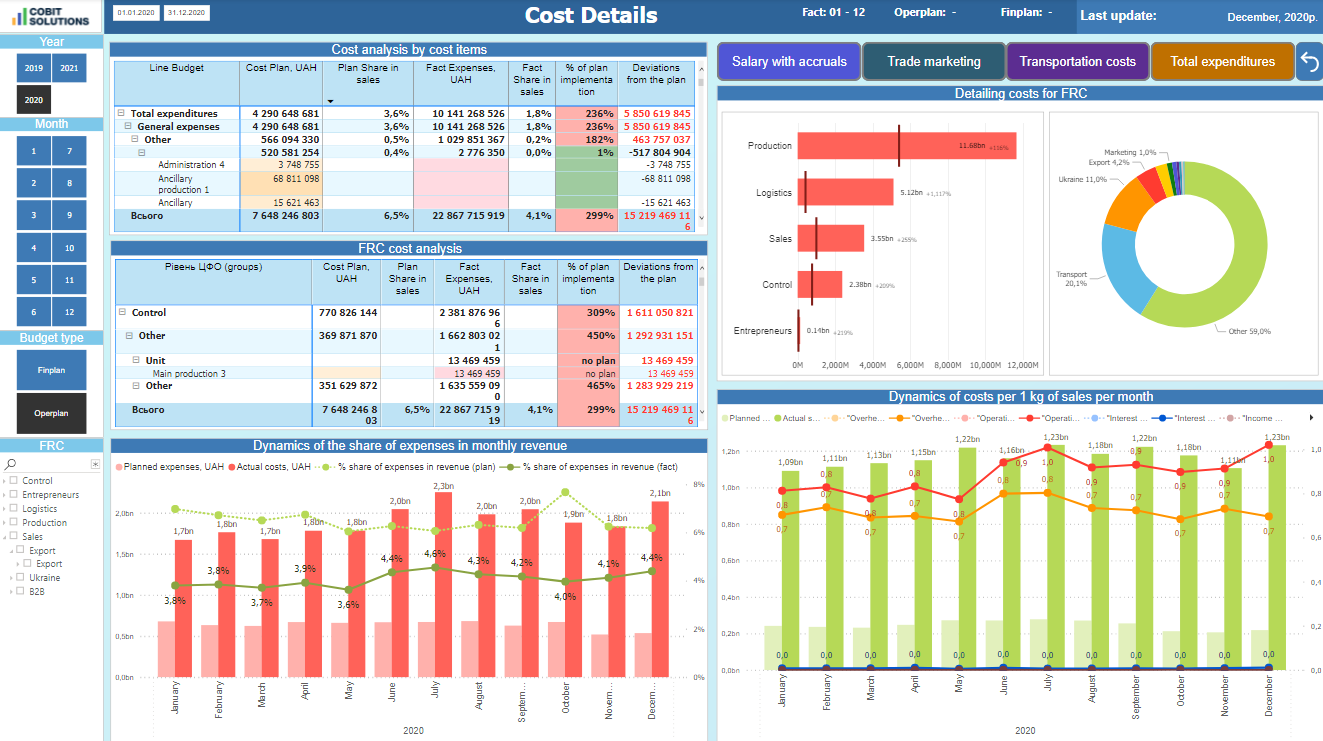

Production cost details is the fifth dashboard connected with data analytics for manufacturing.

It can show different limits and types of goods produced. Here are analyzed finished goods, working progress, semi-finished products, finished products, trade goods, raw materials, spare parts, fuel, etc.

In the first place, the owners get some costs for the first calculation of prime cost. Then, after the next production stage the calculations of prime cost changes with additional costs.

The Advantages of Power

BI Dashboards

Business intelligence in manufacturing is comfortable for usage as you can see interactive reports any time in any place in the world. It is timesaving for the vital decisions of directors and other decision makers.

Dashboards don’t require time for manual calculations as they display refreshed and ready analytical reports. With BI for manufacturing, you can access Key Performance Indicators whenever needed for effective business management, saving time for other tasks within the company and management.

Manufacturing production reports are easy to understand because they are tailored to clients’ needs and design. Each of the department heads will get the necessary data for work and vital KPIs for the company’s success.

Reports are available from any point in the world as manufacturing dashboards use cloud based service and are regularly updated for the moment you see them. Developing the business becomes more comfortable when you regulate the workflows according to the fast reports with interactive analytics.