In today’s fast-paced manufacturing environment, staying ahead means having a complete understanding of your production floor at any moment. This is where real time manufacturing analytics comes in, transforming the way businesses monitor, control, and optimize production processes.

With real-time data at their fingertips, manufacturers can identify bottlenecks, track productivity, and pinpoint problems before they escalate. This not only optimizes production but also helps businesses stay agile in an ever-changing environment.

In this blog post, we will explore the concept of Manufacturing Data Analytics and its key metrics in the modern manufacturing industry.

What is Real-Time Manufacturing Analytics?

Real-time manufacturing analytics refers to the continuous collection and analysis of data from the production floor as it happens. Instead of relying on historical reports or manual inputs, this technology gathers data automatically from machines, sensors, and production systems. The data is then processed and delivered to decision-makers instantly.

This approach allows manufacturers to make informed decisions on the spot, minimizing downtime, improving resource allocation, and preventing costly errors. Real-time data is crucial for process monitoring because it enables manufacturers to respond to changes in production as they happen, rather than waiting for issues to appear in a report hours or days later.

Manufacturers have long used data to improve operations, but real-time analytics in manufacturing takes it to a new level. With this tool, managers have a constant, accurate view of the shop floor, providing insights that help optimize everything from equipment usage to workforce efficiency.

Table of Contents

The Importance of Real-Time Manufacturing Analytics

For manufacturers, the ability to make split-second decisions is invaluable. Production environments are dynamic, and unexpected problems can arise at any moment. Whether it’s a machine malfunction or a bottleneck in the supply chain, waiting to act can lead to lost revenue, increased waste, or missed deadlines.

Real-time manufacturing analytics addresses these issues by providing manufacturers with immediate access to critical data. This allows businesses to respond to changing conditions as they happen, not after the fact. When manufacturers have access to real-time data, they are empowered to:

- Optimize production lines in real time.

- Monitor equipment health and performance.

- Improve overall equipment effectiveness (OEE).

- Track and reduce downtime.

- Ensure consistent quality in production.

In short, real-time manufacturing insights ensure that manufacturers are in control of their processes, even as they unfold, reducing costly surprises and driving better outcomes.

Benefits of Business Intelligence For Manufacturing

The advantages of real time analytics in manufacturing are clear. When manufacturers have real-time data at their disposal, they can better track operations, monitor performance, and make informed decisions. Let’s take a closer look at some of the key benefits that real-time manufacturing analytics brings to the table.

Unified Information Hub

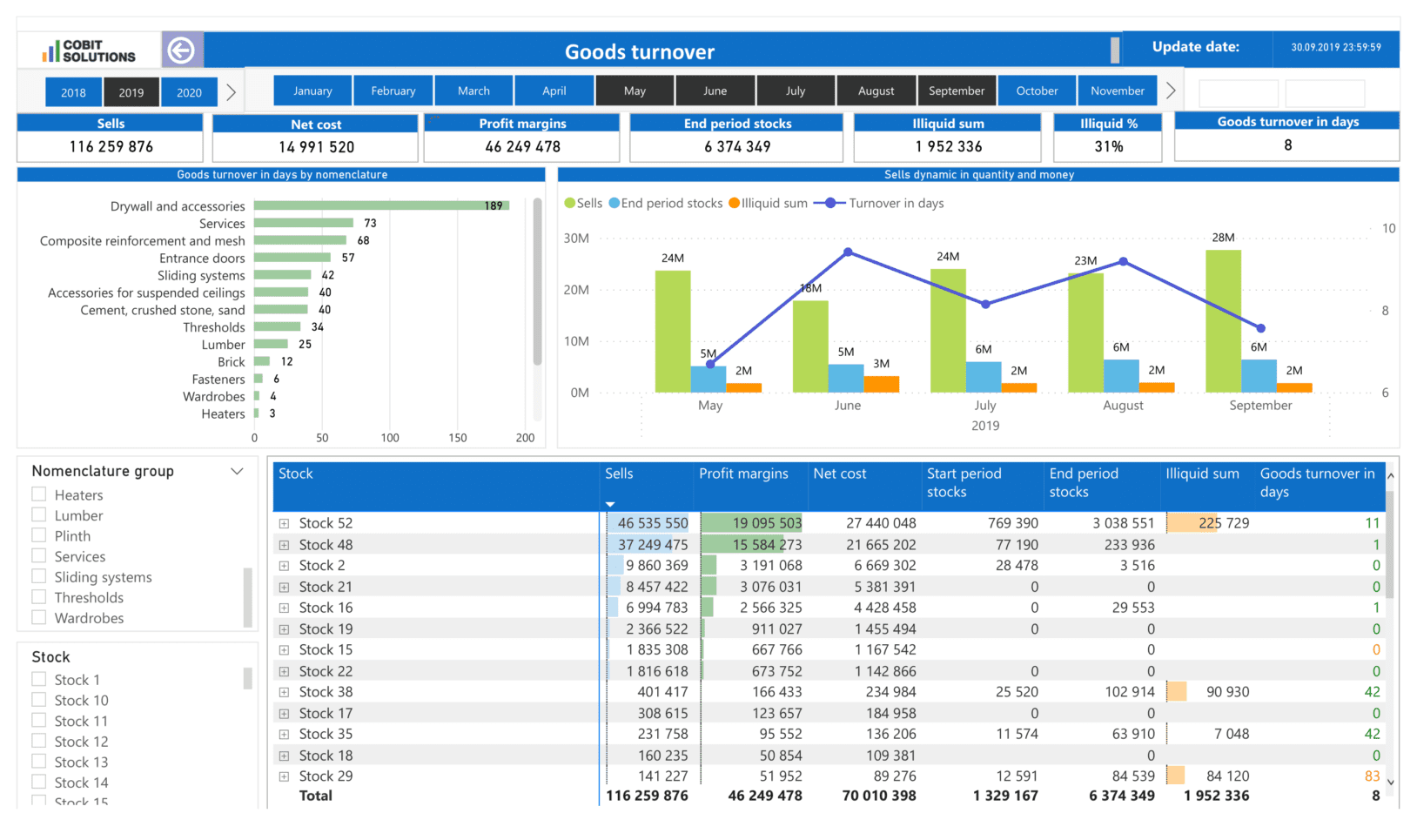

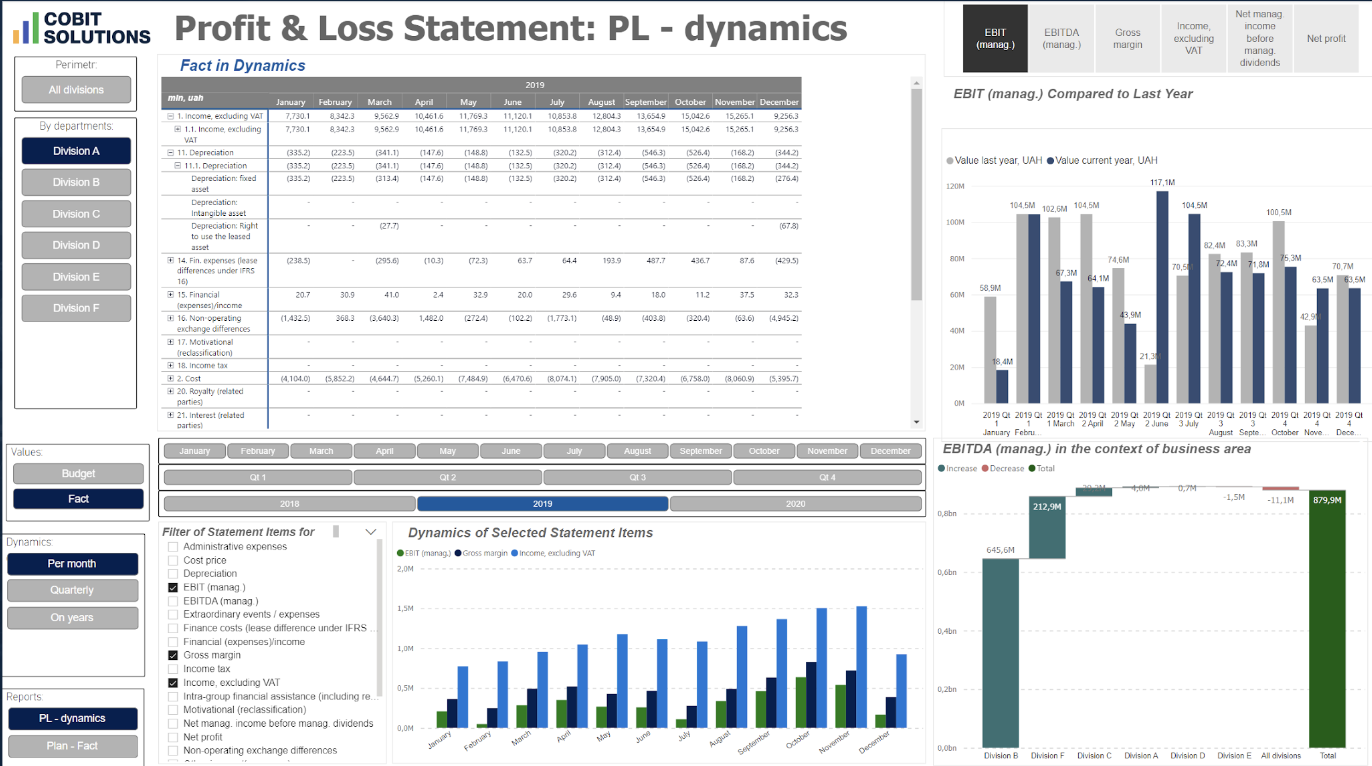

A key strength of real-time manufacturing analytics is its ability to act as a unified information hub. Instead of having data spread across various systems and departments, real-time analytics consolidates all information into a single platform. This includes data on machine status, production metrics, material usage, and more. Having all of this data in one place provides manufacturers with a comprehensive view of their operations. This unified hub ensures that decision-makers have the most up-to-date information at their fingertips, allowing for better coordination and communication across teams.Comprehensive Reports and Dashboards

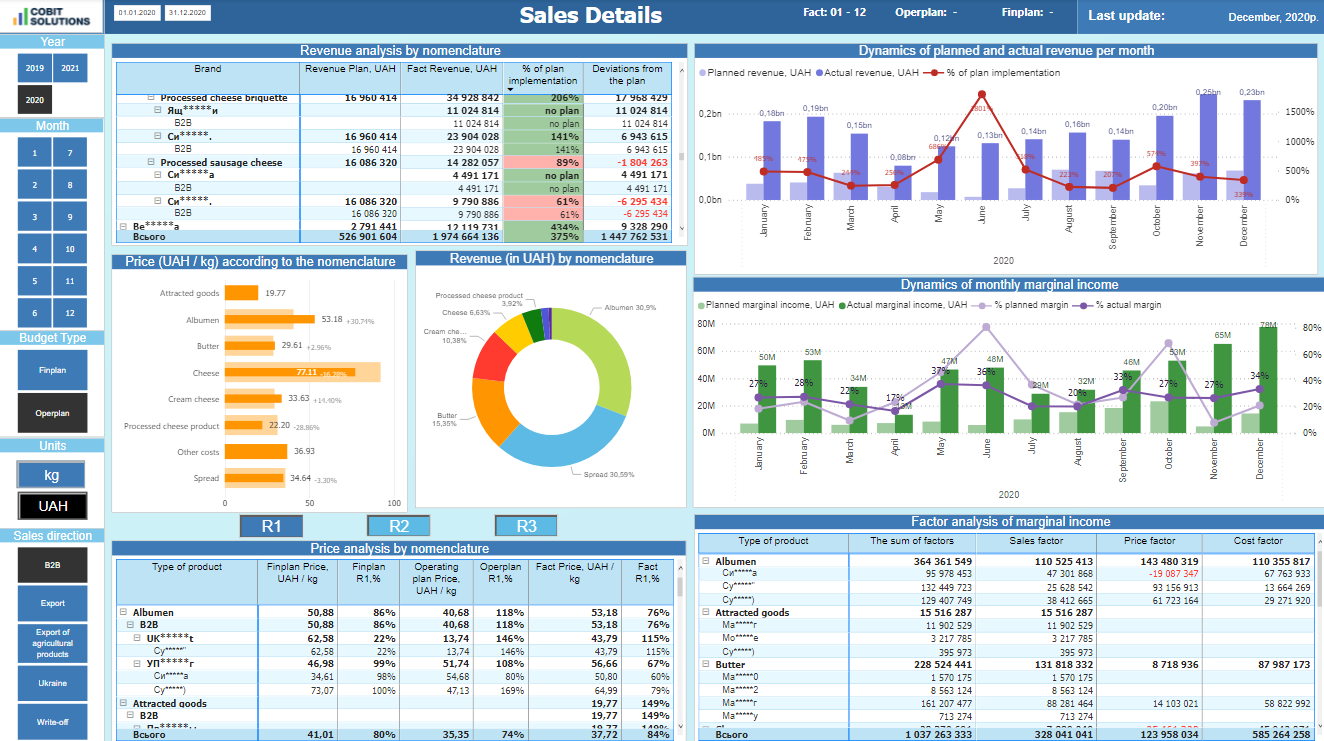

With real-time analytics, manufacturers can generate comprehensive reports and dashboards that provide in-depth insights into their operations. These dashboards can be customized to track specific metrics, such as production speed, machine performance, or material waste.

The ability to filter and sort data in real time allows manufacturers to drill down into specific areas of their operations and identify trends. With access to these detailed reports, businesses can make more strategic decisions that improve long-term efficiency and productivity.

CInstant Intelligent Notifications

BI In manufacturing, timing is everything. Even minor delays or inefficiencies can quickly escalate into bigger issues. Instant intelligent notifications are one of the key features of real-time manufacturing analytics, allowing manufacturers to receive alerts the moment something goes wrong. Whether it’s a machine that needs maintenance or an unexpected production delay, these real-time alerts help manufacturers respond quickly and efficiently. The instant nature of these notifications helps prevent downtime and reduces the risk of quality issues, ensuring that production stays on track without unexpected disruptions.

Enhanced Transparency

Enhanced transparency is one of the biggest benefits that real-time manufacturing analytics provides. Every step of the production process is monitored, tracked, and logged, ensuring that nothing slips through the cracks. With this transparency, manufacturers can ensure that their operations are running as smoothly as possible. This level of visibility is crucial for businesses that need to stay on top of their production tracking. It also ensures compliance with industry regulations, as manufacturers can demonstrate that their processes meet the required standards at all times.

Increased Production Efficiency with Reduced Waste

Efficiency is a top priority for manufacturers, and real-time analytics offers the perfect solution for improving production without compromising quality. By constantly analyzing data from the shop floor, manufacturers can identify inefficiencies in real time and take corrective action. This may involve adjusting production schedules, reallocating resources, or identifying bottlenecks in the process. By increasing production efficiency, manufacturers can also reduce waste. Whether it’s excess materials or unnecessary energy usage, real-time analytics helps minimize waste, which not only lowers costs but also improves sustainability.

Ability to Pinpoint and Address the Underlying Causes of Losses

Losses in manufacturing often stem from a variety of sources, including machine breakdowns, human error, and inefficiencies in the production process. With real-time manufacturing analytics, businesses have the ability to pinpoint and address the underlying causes of losses before they become major issues. Real-time data allows manufacturers to track performance across every aspect of production, providing insights into the root causes of problems. By identifying these issues early, businesses can take steps to prevent recurring problems and minimize losses over time.

Safe Data Transmission

In an age where cybersecurity is a growing concern, manufacturers need to ensure that their data is protected at all times. Real-time manufacturing analytics offers safe data transmission through secure networks and encryption protocols. This ensures that sensitive information remains protected, whether it’s being transferred between machines, stored in the cloud, or accessed remotely.

For manufacturers dealing with sensitive proprietary processes, this level of data security is essential for maintaining the integrity of their operations.

The modern manufacturing landscape demands flexibility, efficiency, and precision. With real-time manufacturing analytics, businesses can achieve these goals by gaining instant access to crucial data that drives better decision-making. From unified information hubs and comprehensive reports to enhanced transparency and instant notifications, real-time data helps manufacturers stay ahead of the curve and optimize their production processes.

By leveraging real time manufacturing insights, businesses can boost efficiency, reduce waste, and identify the root causes of production issues before they lead to major disruptions. And with safe data transmission protocols in place, manufacturers can rest easy knowing their data is secure.

Embrace the future of manufacturing today with real-time analytics and ensure your production lines are running at their best.

The developed perfectly looking Bl templates allow our clients to quickly build their first report in Power Bl and include the most relevant KPIs for reports. – Anna Odrynska, CSO at Alpha Serve

Get in Touch with Us

Ready to use data analytics to revolutionise your manufacturing processes? For professional Microsoft Power BI consulting services, get in touch Cobit Solutions right now. Let us assist you to create unique Power BI manufacturing dashboards and discover the whole possibilities of your data.

The benefits and importance of data analytics in manufacturing are clear. By leveraging data analytics, manufacturers can optimize operations, reduce costs, and improve product quality. From predictive maintenance to demand forecasting, data analytics offers a wide range of applications that drive efficiency and competitiveness. As the manufacturing industry continues to evolve, the role of data analytics will only become more critical.

At Cobit Solutions, we specialize in helping manufacturers implement robust data analytics solutions tailored to their specific needs. Ready to harness the power of data analytics in your manufacturing processes? Contact us today to learn how we can help you achieve your business goals.

Developing the business becomes more comfortable when you regulate the workflows according to the fast reports with interactive analytics.

Dashboards creation

You might also be interested in the article by the owner of Cobit Solutions Why does my company need business intelligence?

Read more on real cases of BI system implementation in different industries on our Blog